European Process Products (EPP) supplied family bakery chain with Koenig Roll Plant-Combi to automate Bread Roll and Ring Doughnut lines, raising production levels and ensuring high quality

Since 1975, Wenzel’s Bakery has bloomed to an impressive 101 bakeries providing ‘the best of baking at reasonable prices’ to its customers across England. The thriving family-run bakery business aims to grow even further with ambitious plans to reach 150 bakeries by the end of 2023.

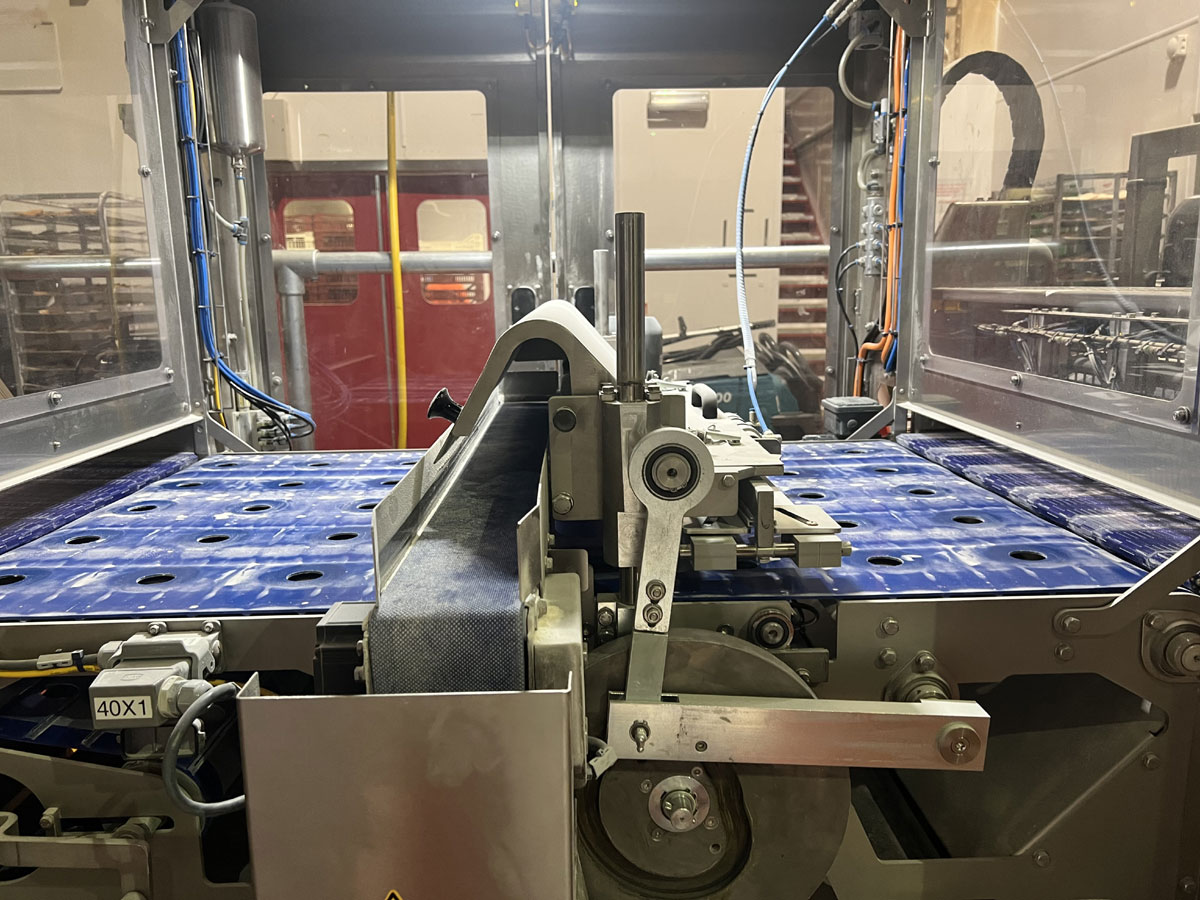

To ensure high quality supplies to its bakeries and to help with this growth plan, Wenzel’s needed to automate some production lines, whilst also ensuring that the quality and consistency of the products was not compromised. European Process Plant Ltd ‘EPP’, well known in the UK for supplying and maintaining high quality industrial baking equipment, advised Wenzel’s on the most appropriate solution to automate five lines covering bread roll and ring doughnut production. The newly installed Koenig Rex Roll Plant-Combi machine now efficiently handles seeded rolls, finger rolls, soft rolls, crusty rolls, and ring doughnuts.

Bart Schmal, Technical Manager for Wenzel’s, a trained baker and food scientist commented, “As a growing and family run business that supplies all our 101 bakeries with freshly baked products daily, we can very quickly adapt to the trends on the market and are constantly reviewing our processes. Having previously worked for a large national wholesale bakery and with Koenig machines, I knew the Koenig Roll Plant machine would be a good fit to help with automation, I don’t know of another machine currently on the market that has the same capabilities; the Koenig machine provides excellent quality and more accurate consistency. We have been able to increase our output and product range as a result. The investment has proved its worth already as, for example, previously on our doughnut line, the holes were stamped out by hand. Being able to automate this process to our high standards has helped immensely with our labour costs as we have been able to divert them to other lines and increasing output.”

Bart Schmal, Technical Manager for Wenzel’s, a trained baker and food scientist commented, “As a growing and family run business that supplies all our 101 bakeries with freshly baked products daily, we can very quickly adapt to the trends on the market and are constantly reviewing our processes. Having previously worked for a large national wholesale bakery and with Koenig machines, I knew the Koenig Roll Plant machine would be a good fit to help with automation, I don’t know of another machine currently on the market that has the same capabilities; the Koenig machine provides excellent quality and more accurate consistency. We have been able to increase our output and product range as a result. The investment has proved its worth already as, for example, previously on our doughnut line, the holes were stamped out by hand. Being able to automate this process to our high standards has helped immensely with our labour costs as we have been able to divert them to other lines and increasing output.”

The Koenig Roll Plant-Combi is a modular system for dough-based products, which delivers high capacity, accurate consistency, high-performance and is customisable for industrial-scale production. The Koenig technology and design of this modular system, means that different lines can be easily and quickly changed and within five minutes to help avoid lengthy downtimes. Steve Merritt, Managing Director at EPP, exclusive distributor for Koenig in the UK and Ireland said: “We’re delighted that Wenzel’s is pleased with the investment of the new Koenig Roll Plant machine, it is a very capable machine that delivers an outstanding return on investment. Wenzel’s is a thriving example of a growing bakery using automation effectively to produce outstanding and consist high-quality products.”

By investing in automation and the Koenig Roll Plant-Combi machine, Wenzel’s Bakery has been able to maintain its high standards, whilst scaling up but with more efficient production processes.

Bart concludes: “We pride ourselves on creating an incredible customer experience, dedicating lots of pace and pounds to innovative product development and our team of highly skilled bakers still hand finish the majority of our products to ensure this quality is maintained. We have found that the Koenig Roll Plant-Comb machine supplied by EPP has helped considerably and would highly rate the equipment and the support and service provided.”

For further information on the products supplied, installed and maintained by EPP, visit or e-mail sales@eppltd.co.uk. To find out more about Wenzel’s – please visit https://www.wenzels.co.uk/.