With ever-rising energy prices exacerbated by the challenging situation in Europe in recent years, it’s wise for bakers to consider their usage and plan ahead. Ovens – and tunnel ovens in particular – are renowned for being the largest consumers of energy in a bakery, which means they need extra consideration in this regard. With energy costs fluctuating seasonally, one method of offsetting these rises is to switch to the cheapest energy source during certain times of the year.

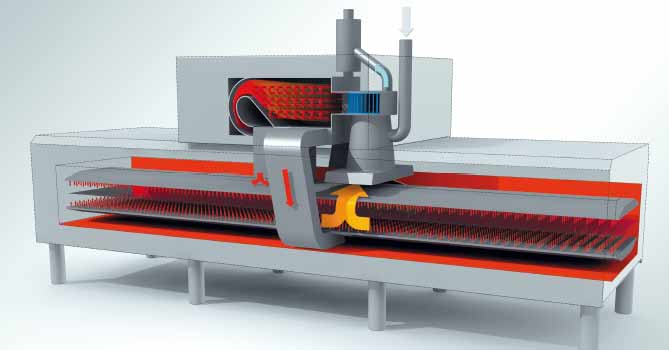

SENIUS direct gas-fired (DGF) tunnel ovens can be switched from its gas-powered heat source to electric by swapping to an electric heat exchanger, which provides up to 300kh/w per ‘zone’. With gas prices increasing in the winter months due to demand, the switch to electricity will allow bakers to save on energy bills. This can then be switched back in summer – when gas demand is reduced – to take advantage of falling prices.

The process is straightforward and can be completed within a day, featuring separate thyristor control. The switch to electric also has the bonus of no combustion gasses and CO2 emission, so no need for exhausts.

The DGF oven is designed to facilitate baking at higher temperatures with increased moisture during the initial stages of the baking process. This method is particularly beneficial for products that require a strong initial heat to set the structure and achieve a desired crust, making them important for products such as biscuits and pizzas.

It’s clear that bakers have been hit hard by rising costs across the board in the past few years, and recent talk of energy price caps will no doubt be causing concern. At EPP we recommend bakers carefully weigh up their product requirements, and opt for a reliable, flexible and energy-efficient solution to help them balance energy challenges throughout the year. To discuss energy usage and how to incorporate flexible solutions into your bakery, contact the EPP team at sales@eppltd.co.uk.