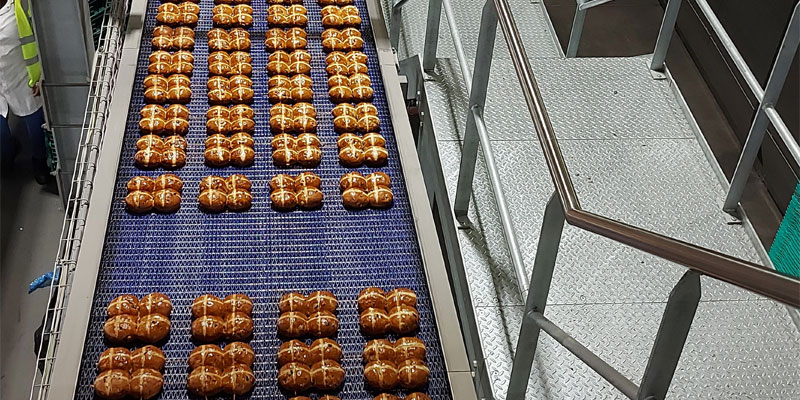

To deliver top quality and consistent bakes for all your hot cross bun and bread roll requirements – whether as part of a fully automated or semi-automated process – European Process Plant Ltd(EPP) has the equipment to ensure a smooth, accurate, reliable and repeatable process.

EPP has the equipment to help produce small batches to large quantities up to 48,000 per hour of hot cross buns. From a fruit hydration tumbling system, ingredient handling for recipe control, mixing, dividing the dough, proving, depositors for the crossing paste, baking and packaging, EPP can help create the perfect and consistent hot cross bun process.

Fruit hydration

EPP has developed a fruit hydration system to solve customer’s fruited dough issues. The clever solution hydrates dried fruit prior to being added to the dough, ensuring the dough is not dried out. The system gives bakers precise control of fruit moisture content.

Ingredient handling

With expensive fruit and spices in use, a precise, consistent and dependable solution is key to prevent overuse of costly ingredients. EPP can supply a fully automated ingredient handling system from leading manufacturer, Shick Esteve. From small craft bakeries to large scale industrial producers – and everything in between – Shick Esteve and EPP can deliver bespoke solutions to receive, store, and dispense ingredients efficiently, accurately and on demand.

Mixing

A gentle mixing solution is important to help protect the fruit and minimise the temperature rise in the dough. Using EPP’s mixing expertise, the team can specify the right mixer and mixing tools to achieve the desired results. VMI offers either a standalone, spiral, or multi-mixer in a carousel to help reduce manual handling.

Dough dividing

In addition to an accurate and consistent dividing process, a system that is quick and easy to clean and maintain helps to ensure quick changeovers. EPP supply equipment from the highly regarded Koenig Rex range that provides the all-important gentle moulding process to create a consistent, repeatable dough piece.

Proving process

EPP’s rack provers are produced by MIWE. The MIWE system provides an even distribution of airflow to ensure a gentle consistent proof. For larger industrial installations a suitable continuous prover can be provided though a number of alternative manufacturers depending on the application.

Cross depositor

EPP can provide a fully automated crossing paste depositor. The depositor works across moving trays to allow continuous flow of the trays and provide a consistent and repeatable paste for the all-important cross application to the buns. State-of-the-art automation ensures the highest quality, even at the most demanding throughput, and the hygienic design allows efficient, effective cleaning during which the depositor can be taken away from the line, with reduced water usage.

Baking

It is critical to have consistency within the bake, with an even distribution of air flow, an accurate control of temperature and an accurate control of the exhaust to maintain humidity levels. EPP has a range of top-grade oven suppliers from MIWE, Koenig and Mecatherm to suit all batch sizes for a fully or semi-automated process.

Spray glaze

Once the buns are baked and de-panned, the buns need to be sprayed with a sweet glaze. EPP can supply a DOJATEC machine that helps minimise waste by targeting only the bun via the pressurised spay system, with the ability to adjust for each dough piece. The DOJATEC machine is also easy to wash down and keep the nozzles clean and has a removal drip tray to collect any excess glaze.

Cooling

From static coolers through to large continuous spiral coolers as well as a variety of blast freezers EPP works closely with a number of suppliers to offer the right solution to meet the baker’s needs.

Packaging

As hot cross buns are frequently batched in packs of four or six – EPP has suppliers that can provide automated flow wrap packaging including the card feeder to help support and protect the products. The systems allow for a quick change over for different packaging materials and printed labelling and dating. Designing systems to cope with large throughputs whilst simultaneously managing the range of different formats and the final packaging flexibility demanded by marketing teams requires attention to detail.

From small batch bakes to large industrial lines, EPP has a range of partners to provide bakers with a solution to meet their requirements throughout the process of producing hot cross buns.

If it’s time to upgrade, upscale or optimise your hot cross or bread bun production line, talk to the team at EPP, who will work with you to recommend the right solutions to meet your needs.

For further information on the products supplied, installed and maintained by EPP, please contact Steve Merritt, telephone 01372 745558 or e-mail sales@eppltd.co.uk.